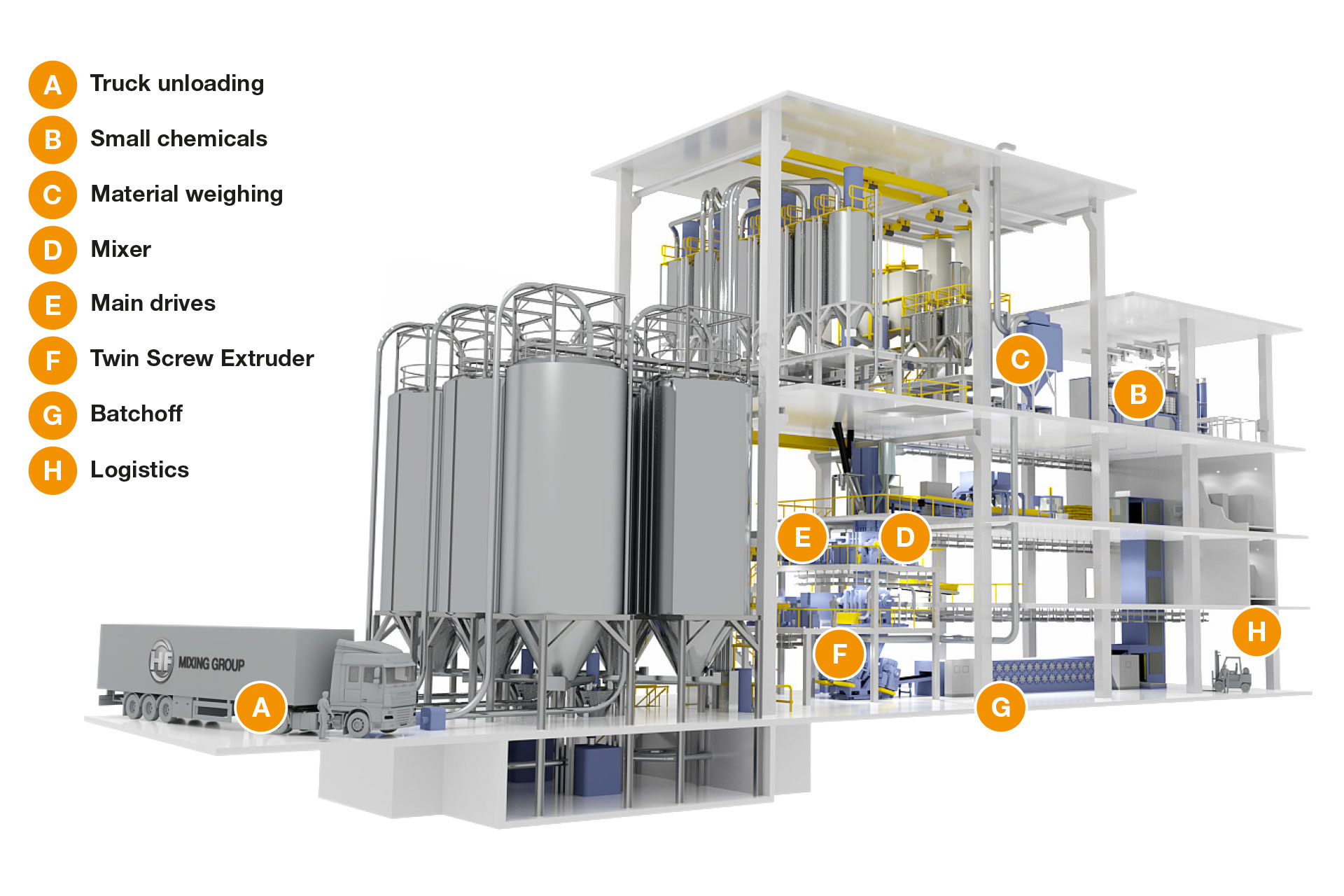

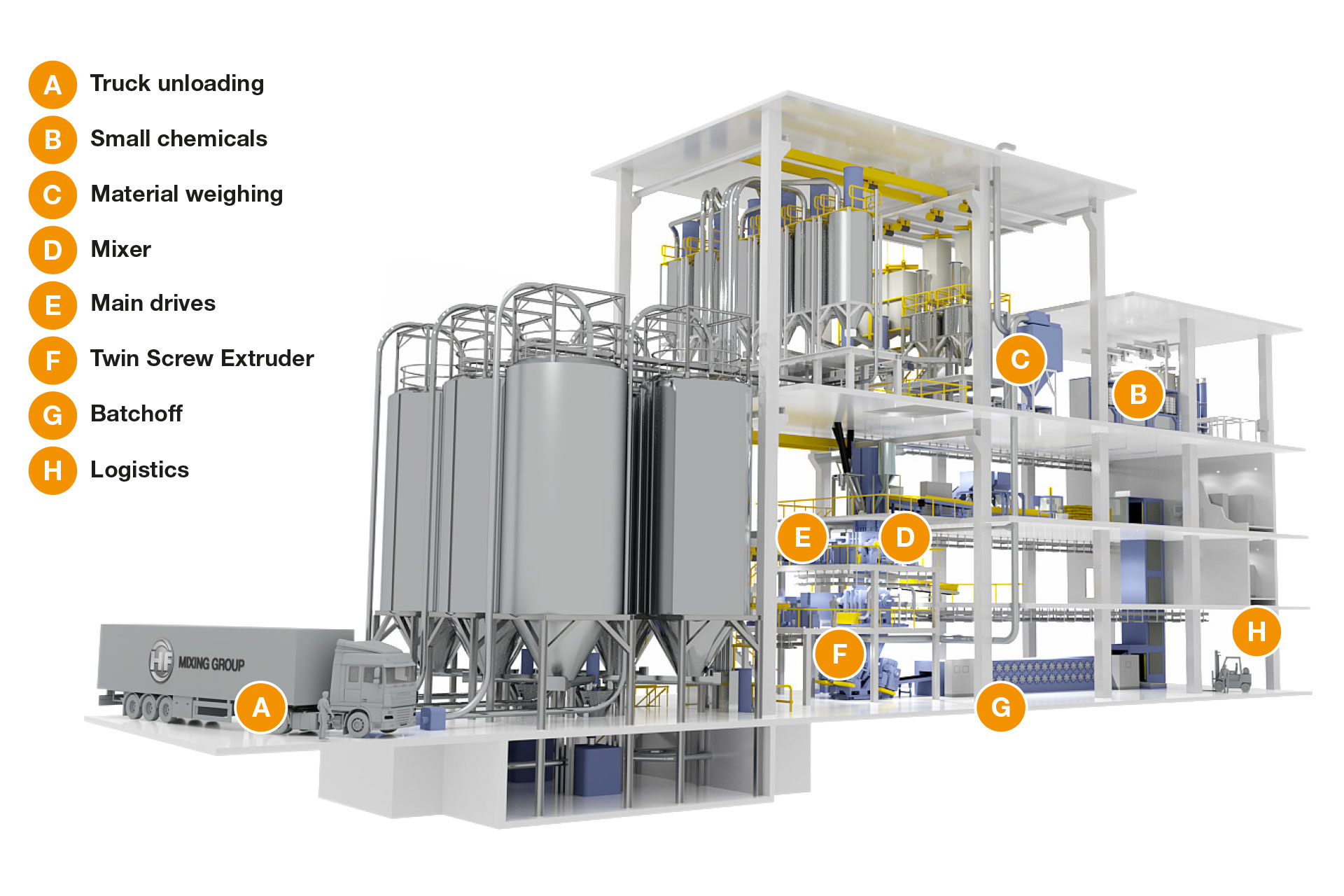

The Mix Vision system provides a complete view of the entire rubber compounding process. This view combined with advanced ease-of-use and a comprehensive operational design, gives the plant floor operators the ability to monitor the rubber compounding process and respond correctly to the typical production issues, reducing downtime and improving consistency. Mix Vision will store and validate the information for raw materials, pre-weighed materials, and mixed compounds (masters, re-mills, and finals). The Mix Vision system controls and tracks the automatic ingredient weighments, manual ingredient weighments, verifies ingredient loading, and controls the automatic mixing cycle completely eliminating mixing cycle variations.

As valued customers of Mesabi Control Engineering we would like to bring your attention to the following end of life (EOL) information for products included in the Mix Vision systems installed prior to 2015.

Unfortunately, we at Mesabi have no control over the obsolescence of the third-party software or components that make up our systems, but we can help you navigate through these situations and provide alternate long-term solutions.

For many reasons products and applications reach the end of their Product Life Cycle. This generally occurs due to market demands, technology innovation and development driving change in the product, or that the product simply matures and is replaced with functionally richer technology and features.

The following items fall into the above categories:

Mix Vision Gen1 while being a stable platform for many years, is at the end of its life cycle due to the changes in computer hardware, operating systems and application software. The new generation of Mix Vision (Mix Vision Gen2) has been designed to run on all current versions of the Windows Operating Systems, including Windows 10 and is less dependent upon PC hardware. The product is faster as result of the change to the overall configuration and application software and provides the end user with many new features and tools.

While the PLC-5 and SLC platforms have been extremely reliable many of their components are already in or beginning to fall into the “Active Mature” or “Discontinued” category by Rockwell Automation (AB). As a result, the hardware associated with this family of product will soon be unavailable as “New” which means after you consume your current spare parts you will be relying on the secondary market for parts as your maintenance strategy.

Our recommendation is to migrate to our Mix Vision Gen 2 package and the Rockwell ControlLogix family of products leaving the PLC5 and SLC legacy products behind you. With a predefined migration plan, minimal conversion time, and a familiar product line for your maintenance and technical support groups; the risk of conversion has been mitigated, and you will benefit from the speed, reliability, and lower cost of the new hardware.

We would be pleased to prepare a detailed proposal to facilitate the migration of your existing system to our Mix Vision Gen2 mixer control system. Upon confirmation of your current configuration, and any additional features you may wish to include, we will prepare a detailed proposal for your review. We are also able to schedule a presentation for you and your staff, via video conferencing, such that you can see the basic functionality of the system, and to share with you many of the additional benefits.

Mesabi, as part of HF Mixing Group would like to thank you for being a valued customer, and we hope that you continue to see the HF Mixing Group as a valued supplier and innovative leader in delivering the best, most reliable Mixing Control Systems available.