Supervisory Functions

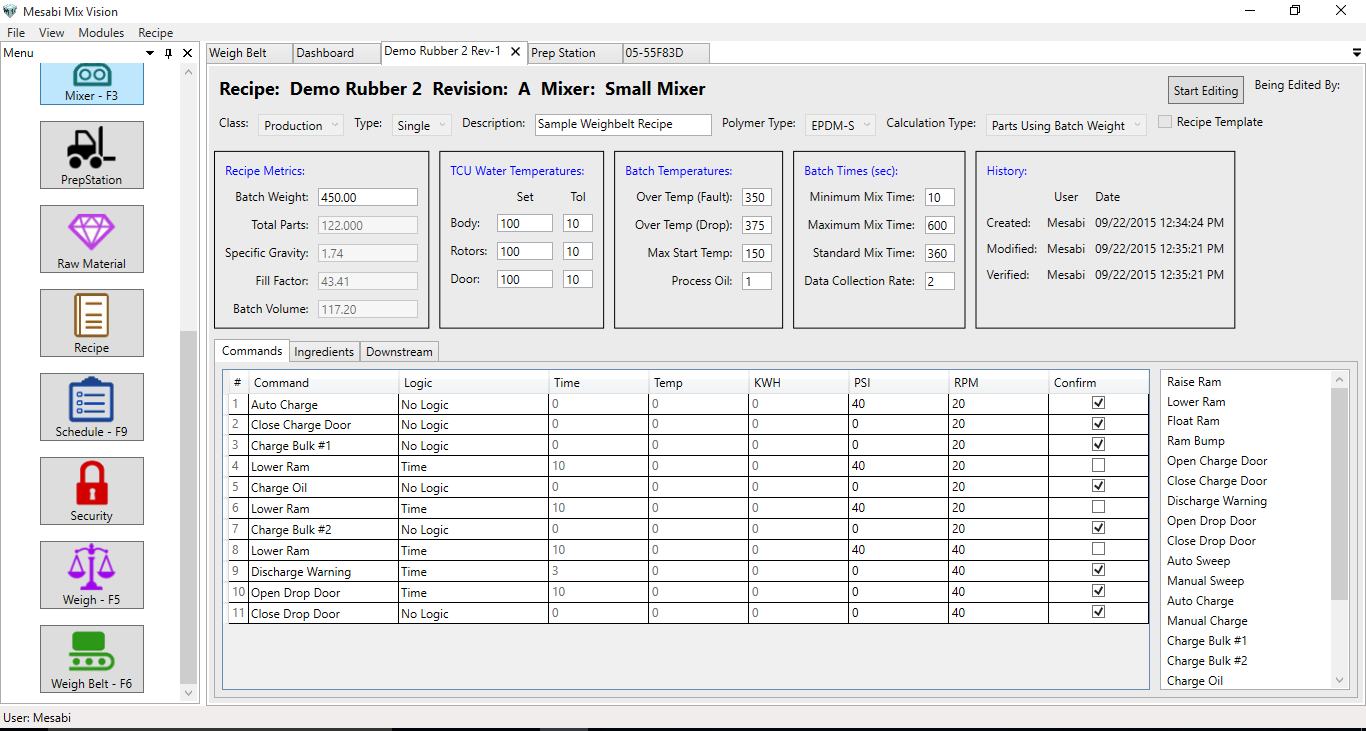

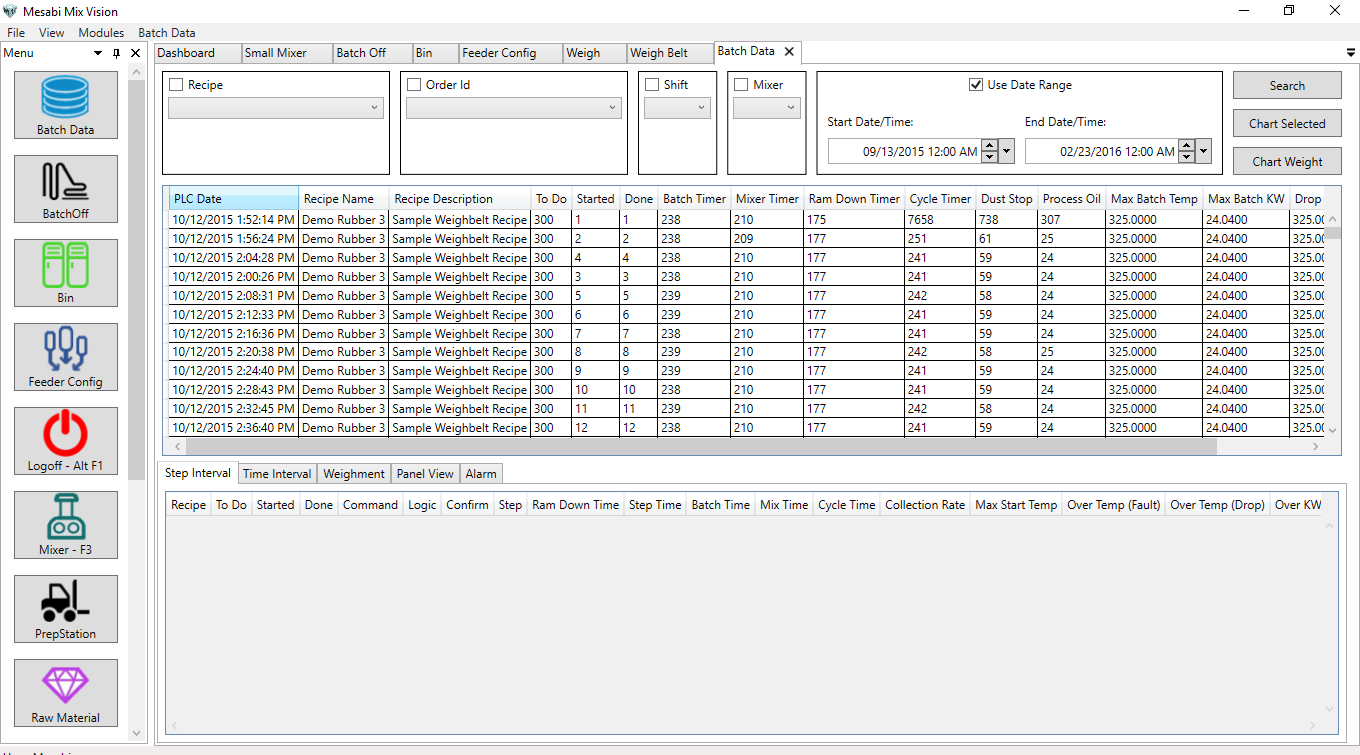

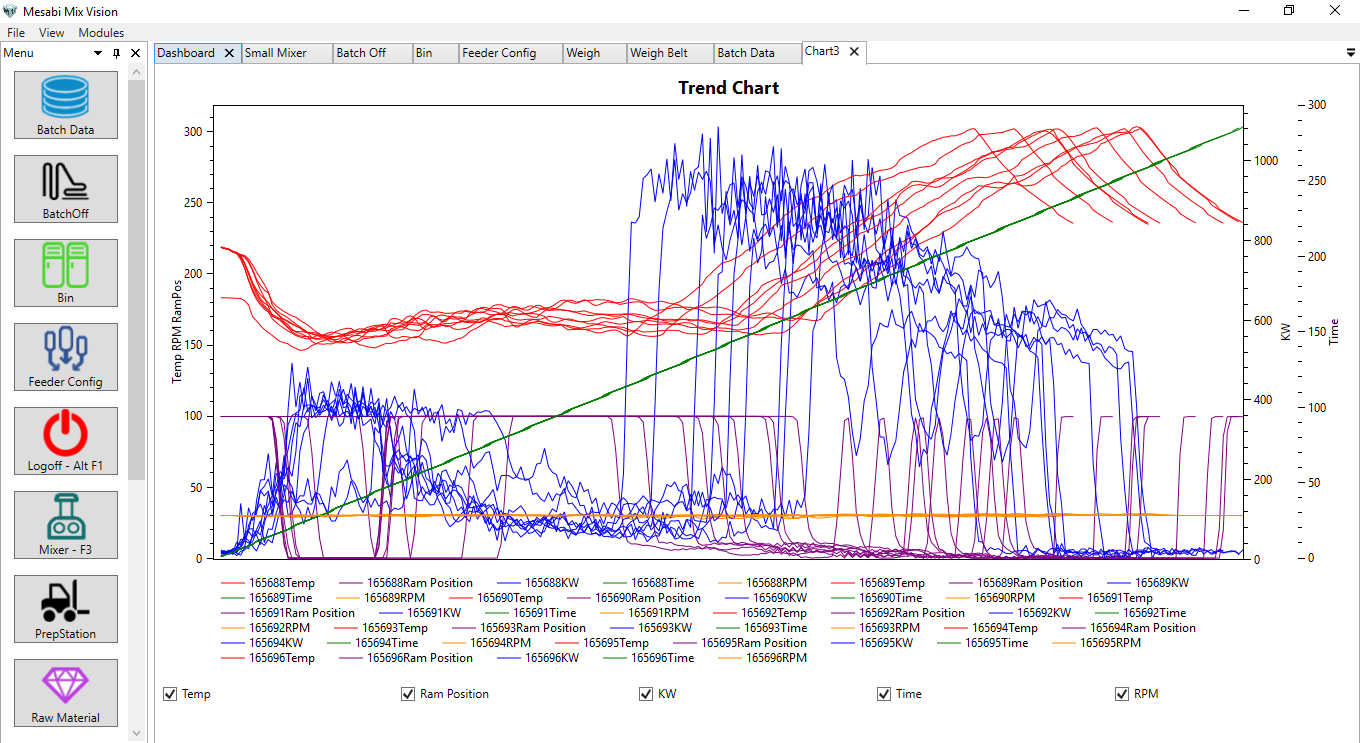

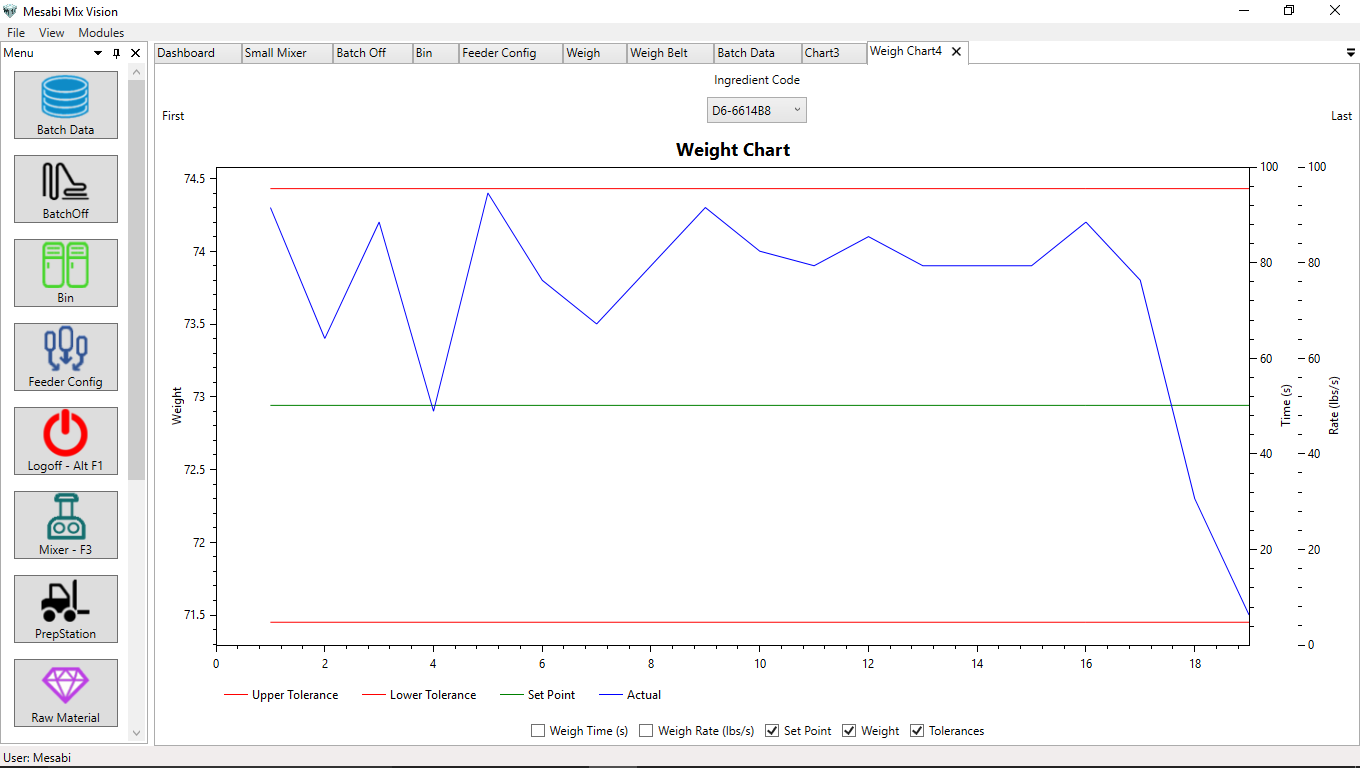

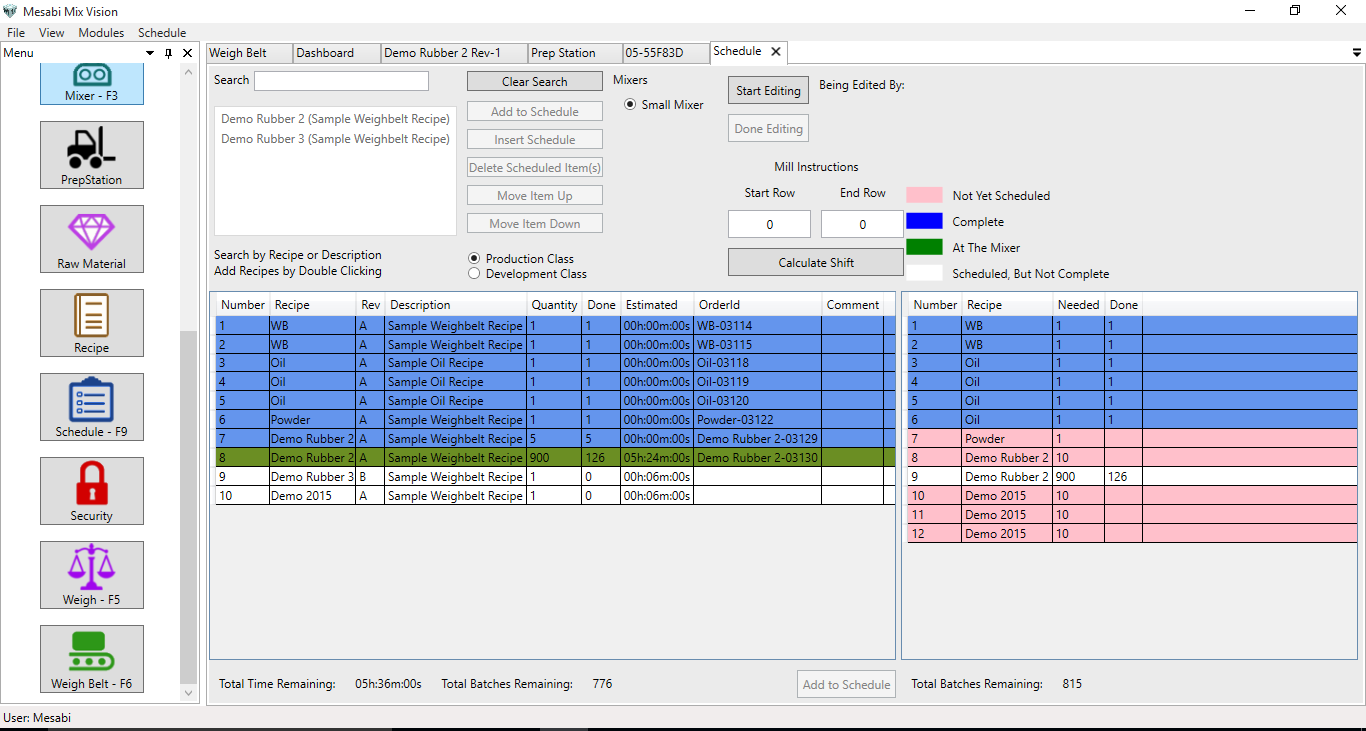

Entry & Scheduling

In Mix Vision orders are entered using this tool and it’s options. Tools are provided to permit entry of order number, recipe name, revision level, quantity of batches or total weight. Compound recipes and mix procedures can be shared between mixers, or variants can be created for mixers having a different capacity and or style of mixing. Schedules may be created, viewed, revised in accordance with the level of security issued to each user of the system. The system also maintains a complete history of the schedule.

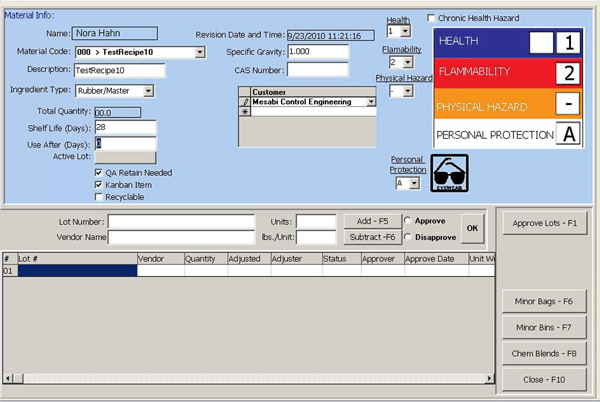

Inventory Management

The inventory management system provides tools for managing raw materials and, where selected, providing full lot traceability via a material tracking package. Through the use of bar code identification labels and readers all raw materials can be traced from receiving through to the mixed compounds upon completion of mixing. On all pages and displays were raw material information is presented the user will also be presented with the associated personal protection equipment data (PPE).

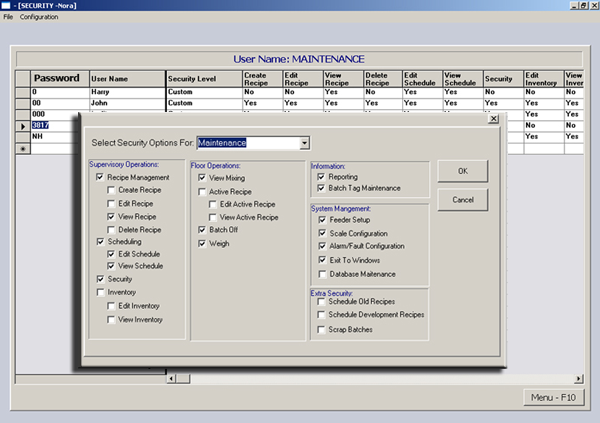

Security

The Mix Vision security provides mechanisms to set up multiple levels of security to control and track access to system operations. Security templates are provided for groups and types of users, which can be tailored and customized to each customer’s requirements.